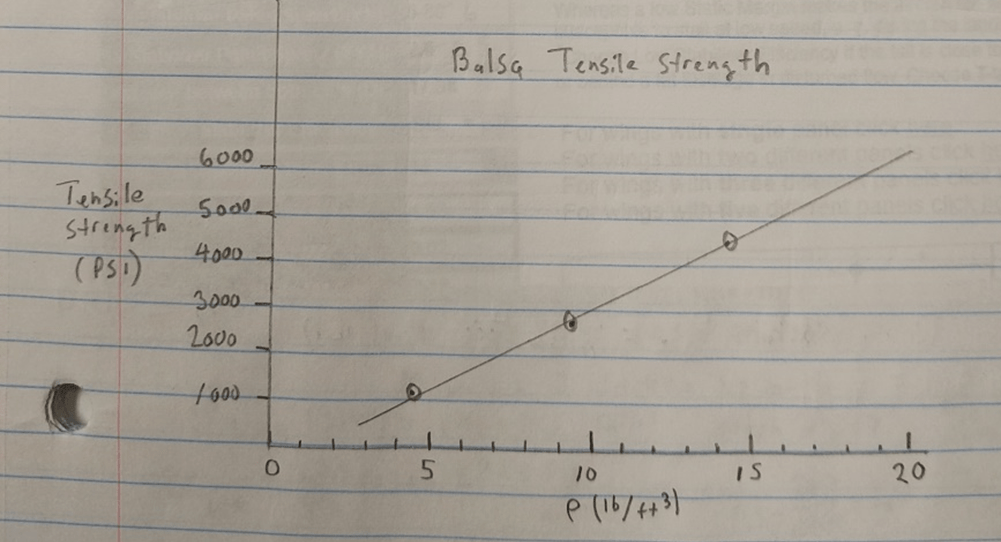

In May 2024, I started building an Embryo model called the Go Devil, a Herb Kothe design and short kitted by Volare models. After finishing all the frames and getting ready to cover the wing I noticed that the wing was quite wimpy and flexible. I could see this wing folding at the flying field with the slightest of wind gust blowing through. Per design, this wing only has a single 1/16 square spar which may work but just didn’t feel very robust to me. So I updated an analysis spread sheet program for wing spar design which have used on several other models which I have built over the years. Assumptions for this analysis are that bending wing load is taken by the main spar with little or no contribution from the tissue covering. The wing is broken up into several panels to approximate the wing plan form shape. I usually start by calculating the bending moment and stress at the wing center which is the reference distance to the inner chord of each panel. One can then proceed to repeat the same analysis at various points along the wing where a different size spar or density wood may be used. For wind gusts I select a maximum lift coefficient of about 1.5 and a wind velocity of 15 mph for the embryo wing. On larger rubber models I would design for higher wind gust of velocities of 20 to 25 mph. It just depends on how much margin you want with the particular wing design.

The spar system which I prefer is an upper and lower adjacent spar joined with a shear web. On larger planes the box beam or D box systems are even better as these also provide excellent torsional rigidity. The shear web is very important as it absorbs the transverse shear and ties the upper and lower spears together. It prevents parallelogramming of adjoining ribs between the upper and lower spars as the wing is bent. Imagine a how floppy a telephone book is because the pages can slide relative to each other when the book is bent, Now if the pages were glued together no sliding occurs between the pages and the phone becomes very stiff. This is transverse shear and why a shear web is critical component to the wing spar system.

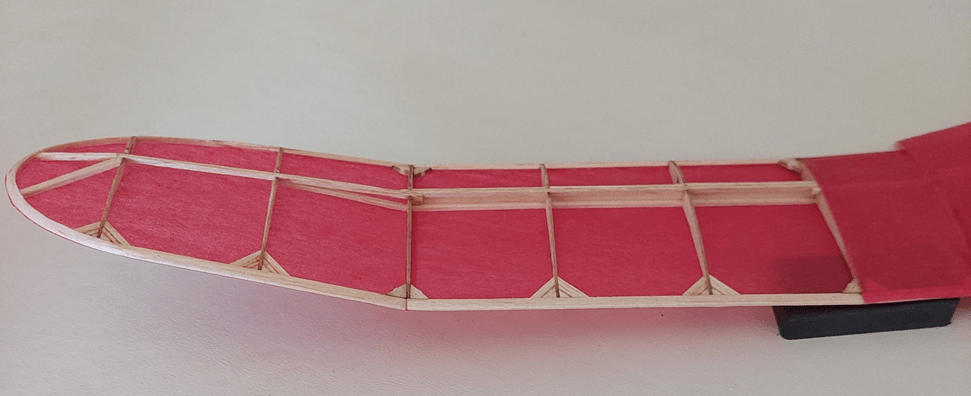

For the embryo wing, based on analysis results I ended up using 1/16 square upper and lower spars joined by a 1/32 shear web for the center panels. The tips had a 1/16 square lower transition spar added to the first tip bay. Based on the analysis results I found that the wing would fold at wing velocity of about 7 mph whereas the redesigned spar could easily withstand a wing gust of 15 mph and still have a factor of safety greater than 2. After making these changes to the wing and doing a simple hand flex test I found the stiffness and strength improvement was dramatic.

Attached is a printout of the spreadsheet program which was used for the Go Devil Embryo model along with a balsa strength graph in PSI versus wood density. If anyone is interested in getting a copy of the program just drop me an Email and would be glad to walk you thru the use of it. Also attached is a photo of the wing construction with the spar design.

Embryo Wing Spar Redesign